A bearing is a tiny round cartridge that is made of steel and houses a ball bearing. A bearing press tool is used for leverage to make wheel maintenance quicker and less challenging. Basically, a bearing press aids in the installation of bearings without causing any damage to the shields.

A bearing is a tiny round cartridge that is made of steel and houses a ball bearing. A bearing press tool is used for leverage to make wheel maintenance quicker and less challenging. Basically, a bearing press aids in the installation of bearings without causing any damage to the shields.

Creating a homemade wheel bearing press is not difficult, and it will save you frustration and potential bearing damage, and all you will need is a threaded rod, a couple of washers and nuts that fit onto the threaded rod.

A wheel bearing press replacement kit may be a great investment for many people, as it allows the operator to change the bearing without affecting the alignment of the wheel. A full kit is usually priced at under $200, and has everything required, to confidently confront a variety of wheel repairs needed, with ease, expertise and stealth.

Different Types

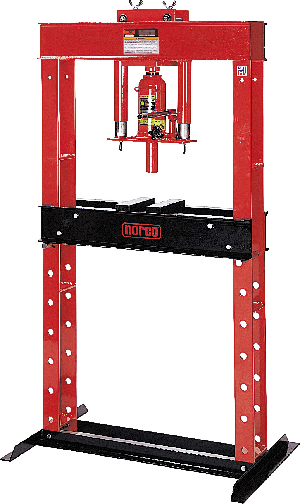

On the other hand, a hydraulic bearing press is considered to be a large mechanical piece of equipment that is used to raise and compress large items. Also known as a Bramah Press (named after its inventor, Joseph Bramah).

During the selection process of pre-purchasing a hydraulic bearing press, the generated force is an important factor to consider. The forced pressure depends on the piston size and the distance it needs to travel. To find out how far a large size piston will move, simply divide the piston head ratio by the distance that a small piston moves.

What Industries Use Them?

Goldsmiths have used hydraulic bearing presses for generations, and it is not uncommon to find a 160 ton wheel bearing press in the jewelry industry today. A 15 ton bearing press is used for minor blanking and other small jobs.

The press operator is mainly responsible for properly placing and feeding the stock into the machine, activating the machine, and then removing the completed material from the machine.

There are physical hazards associated with working with any type of press, especially a hydraulic bearing press or manual wheel bearing press.

Besides tripping and electrical-type hazards, there is also the potential for chemical hazard from the hydraulic fluid, and other type of lubricants, if these chemicals come in contact with human skin.

Due to the fact that bearing presses, especially hydraulic bearing presses, operate with 20 plus tons of pressure, there is the risk that a sharp part may give in and fly from the press with lighting speed, and cause damage to the machine, and more importantly to any humans nearby.