Many of us use the word “laser”, without realizing that it is actually an acronym that means: Light Amplification by Stimulated.

Many of us use the word “laser”, without realizing that it is actually an acronym that means: Light Amplification by Stimulated.

Emission of Radiation

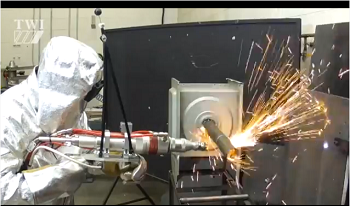

Lasering is used in numerous ways, and among them are a stand-alone and a handheld laser cutter.

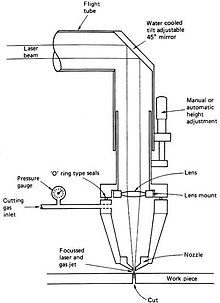

Basically, the energy produced by a laser beam causes a small area to be melted, evaporated or burned away. A laser beam is easily controlled by lenses and/or mirrors, travels in at straight line and travels at lightning speed. A cut is generated when the object or the laser beam is moved across the surface of the material of choice.

CO2 laser cutters are one option where material is cut by using a very focused and high energized beam of light that is created by carbon dioxide. This is used for tiny areas that are required to be cut exactly. It is also powerful enough to penetrate the thickness of a variety of materials.

How does a co2 laser cutter work?

The process of cutting with a co2 laser is achieved, by moving the material/workpiece under the laser/cutting head, or moving the mounted laser/cutting head across the material/workpiece.

The process of cutting with a co2 laser is achieved, by moving the material/workpiece under the laser/cutting head, or moving the mounted laser/cutting head across the material/workpiece.

CO2 laser cutting is ideal to use on plastic, wood, fabric, and acrylic material.

Once the co2 laser cutter is attached to a computer, the system cuts/engraves the designs in the material that you created on the software program.

A gas system is usually used to assist in the process, when a co2 laser cutter is in motion, as this ensures that cuts are continuous with no feathering and minimal cleanup is required. While the cut is being performed, a high pressured jet of inert gas is pointed toward the melting point, during the cutting process. This not only clears away the melted material, but on certain materials, it also increases the thermal efficiency.

Some benefits of using a co2 laser cutter include, but not limited to:

The laser bean never comes in contact with the original piece being cut.

The laser bean never comes in contact with the original piece being cut.- The precision of the cut is unmatched.

- A variety of software can be used, including Adobe, AutoCAD and CorellDRAW.

- Produces clean, smooth finished edges.

- Cost effective.

Who is behind the amazing epilog laser cutter?

Since their inception in 1988, the Epilog Laser Cutter Company has dedicated time and energy into consistently creating and producing high-quality laser systems that they are proud of and the public has relied on. The company, based in Golden, CO (USA), has been delivering the most up-to-date laser cutting technology to small and large businesses, as well as to the craftsman, who operates out of their garage.

The epilog laser cutter provides the highest quality at top speeds, and allows intricate designs to be transferred from the software program to many non-metal types of materials. For extremely thin material, the system includes a special IVT (integrated vacuum table) that will keep paper, fabric and thin plastic material securely in place.

Today, the epilog laser cutter system is used around the world for many different types of applications.