With automated machine tools, the attention is generally focused on loading and unloading work materials.

With automated machine tools, the attention is generally focused on loading and unloading work materials.

However, the expanding range of variants requires a flexible resolution from the building location in order to adjust to the automation procedure to the changing tasks.

From the outside, it’s obvious that machine tools operate automatically. This operation is made possible because of specific aspects of CNC controls, chip conveyors and tool changers. Without being automated, many different machine tool procedures and processes would be much longer.

While flexible retooling is a solution that’s made easier through automated systems, the important question of, “does the machine reach a variety of different work pieces” remains to be an important one.

One of the main objectives with an automated solution is to reduce the gap between the operators and certain operating restrictions. The CEO of Heller Services, Christian Lang, says, “Automation today aims to give support in work piece handling in the face of 24/7 production. The goal is 8,760 productive hours per year”.

Shift Dependency and Automation

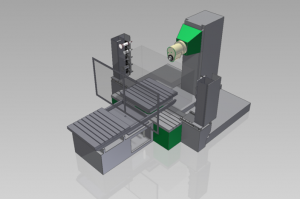

An effective way to increase retooling productivity is by utilizing robot systems or pallet changers. These specific types of machines are typically positioned in front of or next to certain pieces of equipment that need to have their pallets frequently changed.

The problem with the large pallet exchange rate is that there is a high dependency on manual operations. Because of this, daily shift changes can cause extreme backup to the pallet change process.

With overlapping, dependable shift coverage, this issue can be resolved easier than some manufactures realize. In fact, this could be the main reason why your company may not be performing at maximum capacity.

Robot Systems and Pallet Changers

Coming in a variety of different options, pallet changers and robot systems are available depending on the model and size of the machine tool that you use.

Coming in a variety of different options, pallet changers and robot systems are available depending on the model and size of the machine tool that you use.

With options that can carry a weight of up to 3000 kg, there are numerous choices depending on your specific piece of equipment.

In addition, a wide variety of the specialized pallet changers come with robotic systems that provide different unique benefits. Additionally, making these systems more beneficial, grippers, pallets and work pieces can be handled and changed in one quick installation.

Machine Automation

As workloads and overall productivity demands continue to increase, the need for automated machines remain to grow. Some examples of these newly automated equipment types include VL and VSC vertical turning machines.

By having its circulating chain fully equipped with a system that’s automated, drag frames can be installed to allow the movement of materials from the pickup station. This proves to be essential in the vertical machining process.