Milling machines have the ability to accomplish many different tasks because the heads can be changed depending on the type of material being cut and the desired shape of the end results. For instance, if the tool bit is not strong enough to cut through a workpiece (steel for example), the machine may be damaged.

Milling machines have the ability to accomplish many different tasks because the heads can be changed depending on the type of material being cut and the desired shape of the end results. For instance, if the tool bit is not strong enough to cut through a workpiece (steel for example), the machine may be damaged.

On the other hand, if the bit is too strong for softer material (like wood), the workpiece is at risk for damage.

New a Used Milling Machine Basic Parts & Usage

A “cutter” is the most basic tool bit used with a benchtop milling machine, and it is used to cut and shape many different types of material. The cutter is attached to an arbor (also known as a mandrel), which securely holds the cutter firmly in place.

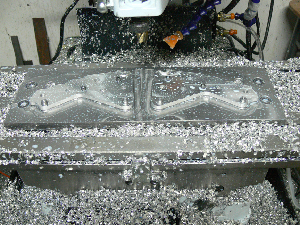

This versatile machine is used in many types of manufacturing shops. A milling machine can be operated manually, mechanically or digitally (via a CNC – computer numeric control panel).

Types of Benchtop Milling Machines

A manual milling machine usually delivers more precision, and is portable and lightweight, which makes it perfect for smaller jobs. Even large companies have a manual version of a milling machine as they are the perfect tool for creating prototypes and completing any light duty work. In addition, manual benchtop milling machinery is usually inexpensive.

Milling machines are usually classified as either vertical or horizontal position (and this simply refers to the orientation of the main spindle).

The recent models of benchtop milling machines are digital, and use CNC technology that requires very little user intervention. CNC milling machine operators still need to be properly trained, to ensure that the machine is operating correctly, and how to input the data and program the computer software.

A benchtop CNC milling machine (also referred to as a “machining center”) is fed specific instructions, via a computer, on how, when and where to cut. This type of machine is more costly and sophisticated than a manually operated milling machine, but CNC milling machines are great for businesses that need to create large volumes of the same type of product.

Bench Top Milling Practical Application

A bench top milling machine resembles a drill press in appearance, but unlike the limitation of a drill press (which you will have to keep the material stable), a bench top milling machine has the ability to move the workpiece toward the cutter.

A bench top milling machine resembles a drill press in appearance, but unlike the limitation of a drill press (which you will have to keep the material stable), a bench top milling machine has the ability to move the workpiece toward the cutter.

Milling machines are used in a variety of industries including, but not limited to: graphic design, gun making, agricultural design and food

Some items that are milled using bench top or other models of machinery include:

- After being casted, car engine blocks are then precisely milled by machine.

- Prior to assembly, a car engine head is also milled.

- Pistons, values, camshafts and some customized items will also pass through a milling machine.

- Gears and other intricate machine parts.

- Scale models.

- Musical instruments.

- Firearms.

Benchtop milling machines are used in many different types of operations, in addition to having the ability to drill and bore through many types of material.

There is such a wide variety in the size, cost and ability of milling machines, so it is advised that you determine how the machine will be used and to take into consideration, what is your price range. Used milling machines will offer the lowest prices on initial investment, and many work as efficiently as new versions.