We have all been there. Whether looking through print classifieds or online postings, we finally come across that specific piece of machinery that is so desperately needed. As we review the product information, it comes to us

We have all been there. Whether looking through print classifieds or online postings, we finally come across that specific piece of machinery that is so desperately needed. As we review the product information, it comes to us

Is this deal to good to be true?

When it comes to making a final decision and determining how useful a discovery is, we must inspect the equipment before purchasing it. This is no different when searching for a functional hydraulic press.

Without question, in order to maintain a high level of hydraulic press productivity, it’s essential to follow a detailed preventative-maintenance (PM) program that has already been created by the machine’s manufacturer.

Hydraulic Press Inspection Steps

Of course, the first step in the process is to find out if the current owner has taken proper care of the machine. You will want to check the cleanliness of the equipment while also inspecting the general appearance of the hydraulic press.

In some cases, you will be able to determine whether the press is a good find just by how it looks. But, don’t rely on exterior appearances alone.

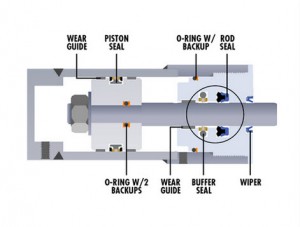

The second step of the inspection process is to understand how a hydraulic press works and the parts that make it operate. By fully understanding the machine’s operational capabilities, anyone searching for a hydraulic press will be able to determine if the machine is in good condition or not.

The second step of the inspection process is to understand how a hydraulic press works and the parts that make it operate. By fully understanding the machine’s operational capabilities, anyone searching for a hydraulic press will be able to determine if the machine is in good condition or not.

This is not only true for this specific piece of equipment, but for other machines too.

The Feed Actuators

Quite possibly the most important component of a hydraulic press is the feed actuators. The physical condition of the feed actuators will be able to determine the exact position of the machine tool and make sure that it adjusts to the proper position in relation to the punch above it.

By ensuring that the feed actuators are functioning effectively, you will be able to determine if the component will stay in place until the metalwork has been completed.

The Pressure Intensifier

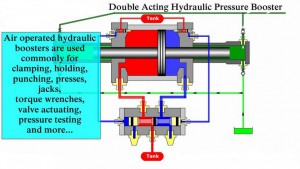

Another extremely important operational part of the hydraulic press is its pressure intensifier.

Another extremely important operational part of the hydraulic press is its pressure intensifier.

In order for the machine to work properly, this component will be completely powered by an air pressurizer that manages the manifold pressure that is controlled by specific valve outputs.

Without a proper functioning pressure intensifier, a hydraulic press is virtually useless.

The Controller

When inspecting the machinery, the controller is the next most important operational component to be found

The controller is a specific computer program that allows the press operator to input certain commands. Whether you need to perform an individual task or a variety of them, the controller is the main part that will allow this to happen.

Inspecting a Machine Tool Online

If you need to inspect used equipment that is being sold online, it can be extremely hard to find the results that you require. In order to receive the proper inspection on a potential hydraulic press online, you will need to use all of the resources available to you.

A good idea would be to ask the seller for a live video of the machine in operation or to take advantage of live video chat software.

If you love working with wood, you can certainly turn this hobby into a satisfying and lucrative career. The main function of any woodworker is to create and repair crafts made from lumber.

If you love working with wood, you can certainly turn this hobby into a satisfying and lucrative career. The main function of any woodworker is to create and repair crafts made from lumber. Cabinet makers are always in high demand, especially for their custom work. Kitchen cabinets, closets and office furniture are just a few of the types of projects that a cabinet maker can expect to be engaged in.

Cabinet makers are always in high demand, especially for their custom work. Kitchen cabinets, closets and office furniture are just a few of the types of projects that a cabinet maker can expect to be engaged in.

Regardless of whether you’re trying to sell your used farm equipment for a new machine or simply trying to unload your old equipment for good, trying to find a buyer can be a very long and drawn out process.

Regardless of whether you’re trying to sell your used farm equipment for a new machine or simply trying to unload your old equipment for good, trying to find a buyer can be a very long and drawn out process.

A milling machine is used when a detailed design is required to be cut into a certain type of material.

A milling machine is used when a detailed design is required to be cut into a certain type of material. for your benchtop mill or CNC mini mill machine is very important. This is an area that you must dedicate a lot of research. You want to choose the best software to meet the needs of the project.

for your benchtop mill or CNC mini mill machine is very important. This is an area that you must dedicate a lot of research. You want to choose the best software to meet the needs of the project.

Following correct safety protocols when excavating is critical. According to a

Following correct safety protocols when excavating is critical. According to a  Know the soil you are working with

Know the soil you are working with

Lifting heavy objects is a fundamental part of human life. Some humans can lift more than others while a few train to lift incredible loads. Eventually, the weight that needs lifting – or the demands of doing so repetitively – exceeds the abilities of one man (or even a group of men).

Lifting heavy objects is a fundamental part of human life. Some humans can lift more than others while a few train to lift incredible loads. Eventually, the weight that needs lifting – or the demands of doing so repetitively – exceeds the abilities of one man (or even a group of men). These cranes are ideal for unloading and loading, construction, and generally moving heavy things around. They have the added benefit of being able to move from place to place – whether on their own or via trailer – without (much) assembly and dis-assembly.

These cranes are ideal for unloading and loading, construction, and generally moving heavy things around. They have the added benefit of being able to move from place to place – whether on their own or via trailer – without (much) assembly and dis-assembly. 4) How does is this crane transported?

4) How does is this crane transported?

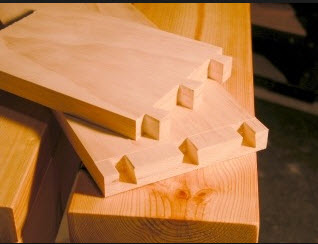

When examining cabinets, frames and other wood furniture that would require interlocking joints, you may see dovetails.

When examining cabinets, frames and other wood furniture that would require interlocking joints, you may see dovetails. Half-blind dovetail

Half-blind dovetail

The manufacturing sector relies heavily on CNC machining as a part of their automated production lines. CNC machining is a computer- controlled process used to control machine tools. CNC machining is a more sophisticated version of computer control because it utilizes unique software in combination with a console control panel to control a variety of machines including lathes, mills, routers, drills and grinders.

The manufacturing sector relies heavily on CNC machining as a part of their automated production lines. CNC machining is a computer- controlled process used to control machine tools. CNC machining is a more sophisticated version of computer control because it utilizes unique software in combination with a console control panel to control a variety of machines including lathes, mills, routers, drills and grinders. CNC machining has several benefits over manual machining. The process is much more precise than manual machining, and once the program is loaded and tested it can repeat the process precisely over and over again, resulting in perfectly manufactured parts that can meet very small tolerances. The resulting parts are identical to one another.

CNC machining has several benefits over manual machining. The process is much more precise than manual machining, and once the program is loaded and tested it can repeat the process precisely over and over again, resulting in perfectly manufactured parts that can meet very small tolerances. The resulting parts are identical to one another. The

The