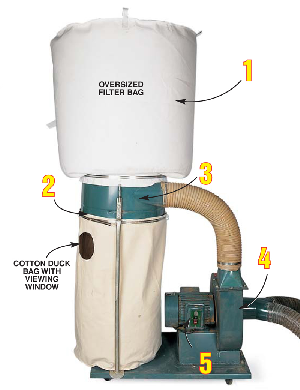

Dust collection systems are designed for one purpose, and that is to keep your workshop clean and free of sawdust. A good dust collector needs to have a strong air flow and a powerful motor.

Dust collection systems are designed for one purpose, and that is to keep your workshop clean and free of sawdust. A good dust collector needs to have a strong air flow and a powerful motor.

Any woodworking shop knows that the initial investment in quality equipment is significant, so it would be illogical not to have a dust collector system in place to protect your employees, and also to avoid the deterioration of the machines that can (and will) prematurely break down due clogging by saw dust.

Worker Safety

Wood dust is inhaled by employees and many respiratory issues are likely to occur. Allergies and asthma are common among people that are exposed to saw dust on a regular basis. In addition to eye, ear, throat and nose irritation and possible skin rashes. Although rare, dust from wood has been linked to nasal cancer.

Any woodworker knows that there is a considerable amount of sawdust that is created when power tools are used. Dust collection systems can be portable, stationary, small or industrial in size. Therefore, there is a type of dust collector for your workshop.

Sweeping wood waste (small particles) with a broom and dust pan may seem like a good alternative, but in reality it adds more sawdust into the air.

Sweeping wood waste (small particles) with a broom and dust pan may seem like a good alternative, but in reality it adds more sawdust into the air.

Some woodworkers may believe that commercial style vacuum cleaners are sufficient in controlling dust that is created by cutting wood, but unfortunately the filtration system does not trap all the micro-wood particles that can cause allergies and respiratory problems.

Not investing in a quality dust collection system will be more costly, as tiny wood chips and dust will not only slow production (because of constant machine maintenance and reduced staff due to illness), but due to the health risks, insurance rates may be higher.

Things to consider when deciding on a dust collection system

Your financial budget is of course a major consideration, as is the location of your machinery and the noise level. Selecting the size of the unit/system is also important, as you don’t want to invest in a system that is insufficient for your workspace.

Your financial budget is of course a major consideration, as is the location of your machinery and the noise level. Selecting the size of the unit/system is also important, as you don’t want to invest in a system that is insufficient for your workspace.

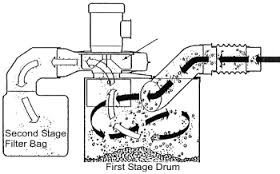

You will need to calculate the air-volume requirements for each machine in your shop, and then decide the type of hookup (such as a PVC pipe, metal duct or flexible hose).

Knowing the type of particles that need to be eliminated from the atmosphere is also important, because finer dust particles need more of a filtration system than larger wood chips. On the other hand, wood chips need a larger storage area in the unit than sawdust requires.

Another major considerations are fire codes and safety issues.