Computer numerical control (CNC) mini lathes are essentially a smaller sized version of an industrial CNC lathe. CNC mini lathes are most often used to produce very small parts more economically than on a large lathe or to machine very small parts that cannot be made using a larger CNC lathe.

Computer numerical control (CNC) mini lathes are essentially a smaller sized version of an industrial CNC lathe. CNC mini lathes are most often used to produce very small parts more economically than on a large lathe or to machine very small parts that cannot be made using a larger CNC lathe.

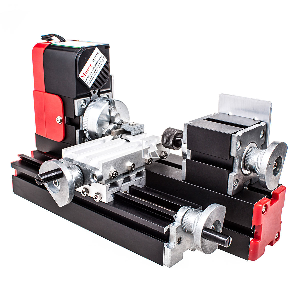

Many mini lathes are designed to fit on a bench top or desktop and other models are designed to be compact and take up only a small footprint on a shop floor.

Lathes are used to make components like shafts and bushings, parts that are cylindrical in shape. In reality, almost all mechanical and engineering devices utilize parts made on a lathe. Lathes are perfect for those who dabble in robotics, race cars, planes, boats, appliances, jewelry and just about any hobby.

Home professionals and hobbyists that create small objects constitute the primary user group for CNC mini lathes. CNC mini lathes and mini machining centers are also used extensively for engineering education and machining training as well as small manufacturing runs.

These mini CNC lathes are used to turn or spin a metal cylinder at a very high speed while it cuts metal to create a new part. Some CNC mini lathes with advanced programming and machine design can even cut complex curves and shapes like their industrial counterparts. Mini lathes are also useful to cut lightweight materials including wax, and plastics.

CNC Mini lathes have a lot of potential to optimize small batch manufacturing and for prototyping and R & D but most CNC mini lathes still have some shortcomings although the technology has definitely improved. It is always best to check with a qualified machinist or engineer to discuss your specific needs and which type of mini lathe or standard lathe best meets your needs.

What to Look for When You Buy a CNC Mini Lathe

There are not too many CNC mini lathes on the market. In many cases lathes come prepared to add CNC controls and in other cases individuals will buy the peripheral equipment and turn a manual or automatic mini lathe into a CNC lathe.

There are not too many CNC mini lathes on the market. In many cases lathes come prepared to add CNC controls and in other cases individuals will buy the peripheral equipment and turn a manual or automatic mini lathe into a CNC lathe.

If you are thinking about purchasing a CNC mini lathe you should make certain that the CNC mini lathe is capable of delivering the accuracy and precision you need for your application.

CNC mini lathes are generally not able to maintain the high levels of accuracy and precision of standard CNC lathes designed for industrial use. Another thing to consider when buying a mini lathe is the durability of the machine and the parts.

A mini lathe should also have enough mass to remain stable during use. If you need to perform multiple operations you should also investigate the work-holding options available and the ease of operation to change tooling.

SIEG

Shanghai SIEG machinery Co., Ltd was founded in 1988. They manufacture mini lathes and milling centers OEM for many different companies. They may well be the premier manufacturer of mini machine tools for DIY, hobbyists and education and training facilities.

SIEG CNC mini lathes feature high reliability, simple operation, 2 axis step motor, high torque brushless motor, metric MT3 spindle, high strength guideway. SIEG also sells a variety of optional accessories and cutting tools as well as stands and a cooling system for the lathe. The CNC mini lathe for DIY and hobbyists comes in two models.

Additional CNC lathe models are available for Education and training and light industrial applications.

Tormach

Tormach designs and manufactures a line of personal CNC machine tools specifically for light industrial and home hobby use. Their duality CNC lathe is unique in the world of CNC machines. It offers two operation modes.

Without your Personal CNC mini milling machine it functions identically to traditional manual mini lathes but when it is mounted on to the bed of the Personal CNC 1100 mini milling machine it becomes a small CNC prototyping lathe that costs only a fraction of the cost of a free standing lathe.

In the CNC mode, the duality lathe is mounted to the PCNC 1100. It uses a rigid quick change lathe tool post that is mounted to the spindle cartridge of the PCNC 1100 and CNC lathe software to provide precise motion of the lathe operations on the X and Z axes.

In the CNC mode, the mill table moves the duality mini lathe left and right while the mill spindle head moves up and down so that all conventional CNC lathe operations are available such as turning, cut off, boring, drilling, and threading. No threading gear changes, radius attachments, or taper attachments are required.

Tormach also offers slant bed compact CNC lathes designed for prototyping and specialty manufacturing of turned parts. It features a cast iron frame, 15” diameter swing over the bed, a 3 HP spindle up to 3500 RPM, a D1-4 Nose with removable 5C taper insert, 25” carriage, rigid tapping capability along with standard conversational control, configurable tooling, optional 8 station turret and full enclosure, work holding and a 12 month factory warranty.

Haas Automation Inc

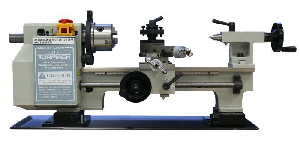

Haas Automation offers an office lathe that is designed to deliver high performance and reliability to industries that cannot fit a standard CNC lathe into their facility. This compact lathe is designed for high production or rapid prototyping of small, precision parts.

This lathe fits through a standard 36” door and into most freight elevators. It also delivers a higher level of precision and accuracy than generally found in other mini lathes.