For many home hobbyists a home laser cutter or laser cutting system makes easy work of cutting precise patterns and etching into plastics, wood, rubber and other soft materials.

For many home hobbyists a home laser cutter or laser cutting system makes easy work of cutting precise patterns and etching into plastics, wood, rubber and other soft materials.

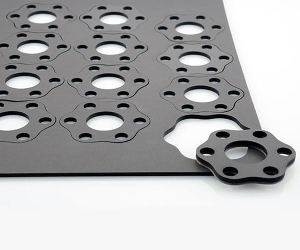

The laser cutting process produces extremely accurate clean, accurate cuts and is especially suitable for high-precision applications although more and more hobbyists are purchasing home laser cutting systems.

How Laser Cutting Works

A laser cutter works by the process of exciting a gaseous medium, most commonly, carbon dioxide to amplify light that gets reflected back and forth many times within the chamber of the laser. The light comes out of an aperture and is then focused by a lens onto a specific point.

A typical laser uses a beam 1/5 of a millimeter in width generating between 1000 to 2000 watts of energy that the laser focuses on a point to melt materials. Lasers lose focus and energy as they penetrate material so cuts are generally limited to a depth of 20 millimeters.

Laser cutting machines are integrated into larger CAD/CAM systems that takes a design file and implements the exact measurements, curves, lines and angles onto the workpiece eliminating the need for hands-on manufacturing.

Most laser cutters allow feautres as small as 1 millimeter in size and specialized laser cutters can achieve even smaller features that allow for the fabrication of micromachinery. Cutting lasers are classified as “class 4” lasers which means that the laser cutting machines are designed to ensure that all cutting occurs within the machine and human operators are never exposed to the laser beam directly.

What Materials Can Be laser Cut?

With many technological advances being made in the high power laser industry there has been a big increase in the types and numbers of materials suitable for laser cutting. Laser cutting can be used on materials with a variety of thicknesses.

With many technological advances being made in the high power laser industry there has been a big increase in the types and numbers of materials suitable for laser cutting. Laser cutting can be used on materials with a variety of thicknesses.

Although laser cutting is more typically used on flat sheets, laser cutters can also cut cylindrical and other geometric shapes. Materials suitable for laser cutting include several types of plastics including acrylonitrile butadiene styrene, acrylics and high density polyethylene.

Laser cutters are used on mylar, nylon and polypropylene although these materials are more unpredictable in how they melt during the cutting process. Ceramics, certain grades of foam such as depron, gatorfoam and expanded polystyrene, paper, leather, rubber, magnetic strip, balsa and medium density fiberboard among other woods are also suitable for laser cutting. Finally several metals can also be cut using lasers and these metals include mild steel, stainless steel and aluminum.

Types of Lasers

There are basically three types of lasers used for cutting. The CO2, the neodymium Nd, and neodymium yttrium-aluminum-garnet or Nd YAG lasers. These lasers do not work equally well on all materials so it is important to know what material or materials will be cut and whether or not the laser under consideration is suitable for the material.

It is always wise to consult with a laser- cutting engineer or manufacturer to understand what models are best suited to the cutting application in question.

Three Dimensional Laser Cutting

A three-dimensional laser cut is similar to a regular laser cut. The major difference is that the laser, in conjunction with a computer driven program can recognize all sides of a substrate material and not just the face of the material. 3D laser cutters are able to work on cubed materials or other large substrate shapes and not just flat materials.

A three-dimensional laser cut is similar to a regular laser cut. The major difference is that the laser, in conjunction with a computer driven program can recognize all sides of a substrate material and not just the face of the material. 3D laser cutters are able to work on cubed materials or other large substrate shapes and not just flat materials.

The substrate material can include glass, crystal, metals and woods. In 3D laser cutting the laser can be programmed to cut the inside of the material as well as the surface. This is a common process in the cutting of crystal.

Hobbies Appropriate for Laser Cutting

Laser-cut art hobby products can be made in a variety of materials including wood, metal and paper. Types of art you can create include earrings, wall screens, wood furniture, cards, puzzles, toys, sculptures and more.

With advanced computer programs laser cutters can be used to create 3D models and artwork. Engraving is one of the most common uses for a home laser cutting system.

Hobby Laser Pricing

Home hobby Laser cutters can be bought for as little as $1,500 if you chose a cheap imported model but many of these cheap laser cutters lack features and do not come with clear, easily understood directions. They also tend to require new gas tubes more often than slightly more expensive professional grade laser cutting machines you can purchase for around $3,000-$5,000.

Safety should be a concern so it is always better to buy a professional standard machine. Imported machines may not conform to industry safety standards.

Cheaper models may work okay for two-dimensional laser cutting but if the machine will be used for sculpting or etching one should consider a professional laser cutting system with advanced features and computer numerical control (CNC) that easily handles complicated shapes and 3D Cutting.

CNC controls also which eliminates the need for manual operation and increases accuracy. CNC lasers are considerably more expensive but can be a worthwhile investment for a small home business.

Conclusion

Although it is easy to find home laser cutter systems for sale online or second hand at cheap prices it is important to carefully consider how the home laser cutting system will be used, safety concerns, and cutting materials. The hobby laser cutter must be appropriate for the materials it will cut and thought must be given to the degree of complexity and accuracy required for the production of the products.

The best advice is to seek the assistance of a qualified laser-cutting manufacturer to help identify the best laser cutting system for the type of cutting required as well as the materials that the laser will cut. Good research and information will save a lot of hassle, wasted money and frustration.