The difference between a CNC router machine and hand held router, is the fact that the tool follows a path via a computer control, instead of being guided by hand.

The difference between a CNC router machine and hand held router, is the fact that the tool follows a path via a computer control, instead of being guided by hand.

There are two software programs involved: CAD (which makes the designs) and the CAM (which communicates these designs to the machine).

This computer controlled machine is ideal for cutting a variety of material, such as steel, aluminum, plastic, foams, composites and wood.

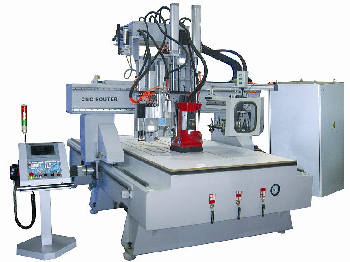

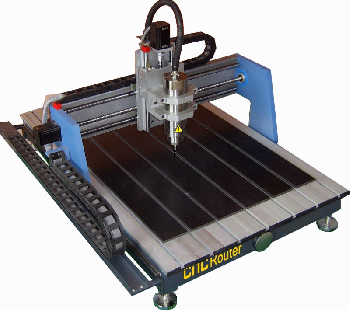

The sizes and configurations of a CNC router vary drastically, from the small desktop version, to the industrial size – which is often used in boat and cabinet making shops.

Even though the sizes may differ, there are some CNC router parts that are common among all machines:

Controller

A CNC router machine is usually controlled via a computer and specific software, but it can also be controlled manually. On the control panel you may find a “reset” button, a manual control switch and a “stop” button for an emergency shut- down of the machinery.

Spindle

The spindle is the part of the CNC machinery that does the actual cutting. Spindles are categorized by their power output. The speed of the spindle is dependent upon the type of material being cut.

Linear Guides

Linear guides, also referred to as rail systems or linear block guides, basically leads the spindle in the direction of the axis, with little or no friction. The rail guides the blocks, and allows for a smooth ride as the load is moved.

Simply think of this concept as a roller coaster – the “rail” is the track, and the “block” being the cars traveling along the track.

CNC Router Kits

There are a few things to consider before purchasing a CNC router kit, and the first being the size needed for your project. For example, will you be cutting guitar shells from wood? Or building a canoe? Or processing the same template all day?

There are a few things to consider before purchasing a CNC router kit, and the first being the size needed for your project. For example, will you be cutting guitar shells from wood? Or building a canoe? Or processing the same template all day?

It is recommended to think about the largest piece you plan to cut, and to plan your router kits based on that measurement. In addition, the workshop area may also be a factor in your decision making process.

Some will come with a computer, while other kits will only have the software included. For this reason, it is important that you know your computer needs before making the purchase.

A quality kit should come with a variety of bits. In some kits, there will be a feature that will change bits automatically (but expect to pay extra for this convenient feature).

Before your final decision is made, it is important to notice the speed that is included within the CNC router kit. A slower machine may initially save you some money, but if you need to meet deadlines of large quantities of product per day – it may be more cost effective to purchase a quicker cutting machine. A slower CNC router is fine for a hobbyist, who is looking to save money and does not have a tight deadline to meet.

Final Word

A CNC router machine is a boring machine, panel saw and spindle moulder, all wrapped up in one great machine. It not only reduces waste and errors, but it allows a finished product to get into the public market, in a shorter period of time.

The products created with the assistance of this machinery are numerous, they include (but certainly not limited to): musical instruments, furniture, doors, frames, paneling and decorative carvings.